Three dimensional printing technologies represent a manufacturing revolution because of their unique capabilities for increasing shape complexity while reducing waste material, capital cost and design for manufacturing. However, the application of 3D printing technologies for the fabrication of devices remains an almost unexplored field due to their elevated complexity from the materials and functional points of view. The use of 3D printing technologies in energy and environmental applications is of special interest since the related devices usually involve expensive advanced materials such as ceramics or composites, which present strong limitations in shape and functionality when processed with classical manufacturing methods.

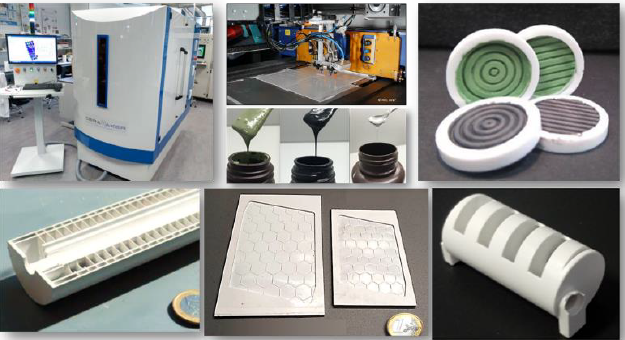

Among other technologies, Solid Oxide Fuel and Electrolysis Cells (SOFC/SOECs) are one of the candidates to strongly benefit from 3D printing. SOFC/SOECs are ceramic-based multilayer complex devices able to efficiently generate electricity from clean fuels like hydrogen (fuel cell mode) as well as store renewable electricity in the form of transportable gases (electrolysis mode). In the last years, we have been developing an innovative 3D printing technology able to fabricate free-form complete SOCs with up to 60% of improved performance even using state-of-the-art materials.

The project Cell3ditor has been awarded as the most innovative FCH-JU project 2019, and with the Solar Impulse Label on April 2020.